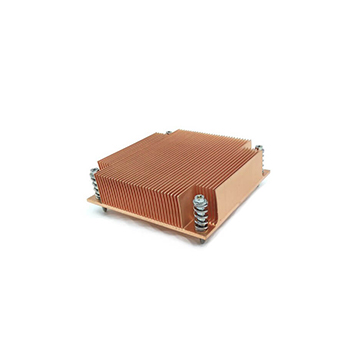

Custom radiator

Our custom radiators include steel radiators, copper-aluminum composite radiators, stainless steel-aluminum composite radiators and aluminum alloy radiators, radiators are the main equipment in heat exchange devices, and radiators are widely used in hot air heating, air conditioning, refrigeration , condensation, dehumidification, drying, etc. Our custom radiators can be used in light industry, construction, machinery, textile, printing and dyeing, electronics, food, starch, medicine, metallurgy, paint and other industries.

Product display

![]()

Product introduction

1. Steel radiator: At present, the common products on the market are suitable for central heating and have many styles. Since steel cannot be anti-corrosion, attention should be paid to internal anti-corrosion when purchasing. In order to ensure smooth circulation, large waterway products should also be selected.

2. Copper-aluminum composite radiator: Using the characteristics of copper anti-corrosion, the inner tube of the radiator is made of copper, and the outside is made of aluminum wings with good thermal conductivity. It seems to be a perfect combination, but there may be fatal defects: copper is used as the inner tube wall of the radiator, which is generally very Thin, but China's heating water quality is very poor, there are a lot of hard impurities, and the copper itself is very soft, it is easy to wear, and there are often accidents of copper-aluminum composite inner pipes bursting. In addition, the thermal expansion rate of copper and aluminum is very different, and after a long time, there will be a "core off" phenomenon, and the heat dissipation rate will drop significantly.

3. Stainless steel-aluminum composite radiator: The upgrade on the basis of copper-aluminum composite radiator, stainless steel is not only anti-corrosion, but also hard, but stainless steel welding technology is not as mature as steel radiator welding, so it is ok to choose a big brand manufacturer, a small brand Use with caution.

4. Aluminum alloy radiator: First of all, it should be emphasized that aluminum radiator can never be used in China's central heating system. However, for the heating of wall-hung boilers, there are currently aluminum alloy radiators for wall-hung boilers launched by manufacturers on the market. The inner tube is small and the heat dissipation is large, which is a very good energy-saving choice for self-heating.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Shenzhen Sunbright Technology Co., Ltd. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.