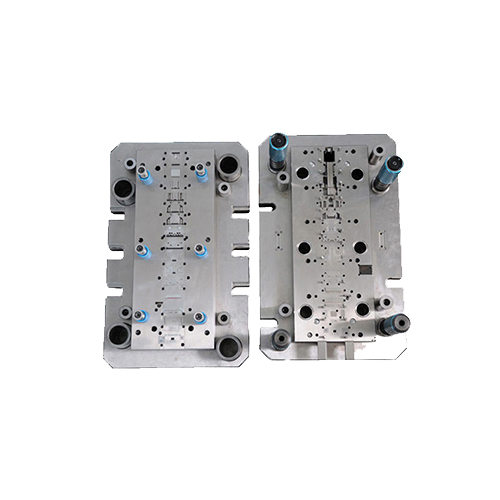

Metal Stamp Moulds

1.Metal Stamp Moulds Introduction

Rolling or sheet metal is used in the comparatively easy process of metal stamping. It is put into a press with a die that forms the part into the required shape.

The die is forced into the metal by compression and force.

A partially finished portion is removed after a set period of time.

Even though it could seem fairly simple to comprehend, there are actually a number of phases that must be followed, such as cutting, finishing, and other processes intended to create the final product.

These expertly crafted metal stamping molds are produced using precise metal shapes and exact specifications.

A metal stamp mould is a tool used in the manufacturing process of metal stamping, which is the shaping, cutting, or molding of metal sheets into predetermined forms or patterns. Numerous metal goods, including hinges, brackets, enclosures, and other components, are produced using this technology.

A precise tool, the metal stamp mould is usually constructed from hardened steel. Its distinctive design matches the intended form or style of the metal object that is being manufactured. A significant degree of engineering and technical knowledge is needed to complete the intricate process of making a metal stamp mold.

Our metal stamp molds are meticulously built and designed with the most recent CAD software to guarantee accuracy and uniformity in the finished product. We make use of premium materials, such as hardened tool steel, to guarantee the molds' endurance and best performance during the stamping process.

A piece of sheet metal is positioned between the metal stamp tool's upper and lower dies during the metal stamping process. After that, the upper die is forced down onto the metal to form the required shape or pattern. The most recent technological advancements are incorporated into our stamping machines to guarantee an accurate, effective, and secure metal stamping procedure.

We provide metal stamp mould design, manufacture, and maintenance services at our facilities. Custom metal stamp mold design and production are our areas of expertise, serving a variety of industries such as consumer products, automotive, aerospace, and electronics.

In conclusion, metal stamp molds are crucial equipment for producing a variety of metal goods by metal stamping. Our meticulously designed metal stamp molds, crafted from premium materials, provide uniformity and precision throughout the metal stamping procedure and are an essential component of our production process.

2.Metal Stamp Moulds Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

3.Metal Stamp Moulds Feature And Application

Metal stamp molds have the following qualities: accuracy, robustness, and adaptability. To guarantee that metal stampings are reliable and accurate each and every time, metal stamp molds are designed to rigorous specifications. Additionally, they are strong and designed to survive the tremendous pressures and strains involved in the metal stamping process. Furthermore, metal stamp molds are adaptable, enabling the creation of components in a variety of sizes and shapes.

Applications for metal stamp molds are numerous and include:

Automotive - Body panels, brackets, and other components are produced in large quantities by the metal stamping industry.

Aerospace: Parts for helicopters, planes, and spaceships are made by the aerospace industry using metal stampings.

Electronics: A vast array of electronic products, including computer components, smartphones, and audio equipment, are made using metal stampings.

Consumer products: A variety of consumer goods, such as jewelry, appliances, and tools, are made using the metal stamping method.

We provide a wide range of sectors with metal stamp mould design, manufacture, and maintenance services at our facilities. High-quality, precisely manufactured metal stamp moulds that meet or surpass the most stringent industry standards are produced by our skilled engineers and technicians using the most recent CAD software and manufacturing tools.

All things considered, metal stamp molds are an essential part of the metal stamping process that enable the creation of precise, high-quality metal components for a variety of sectors. We pledge to provide our clients the best metal stamp molds possible to satisfy their unique requirements and uses.

4.Metal Stamp Moulds Details

A mold used in precision metal stamping is often made up of two or more half-shells that are arranged to define a certain area of the space and correspond to the desired shape of the component to be stamped.

Typically, the production molds are composed of tempered or hardened steel.

These expert stamping metal molds are rigorously controlled in compliance with the NADCAP - NDT certificate standard and ISO 9001 and AS9001 standards.

We have a thorough quality control system and fully functional measuring equipment to ensure good quality.