Precision CNC Components for the Medical Industry

1.Precision CNC Components for the Medical Industry Introduction

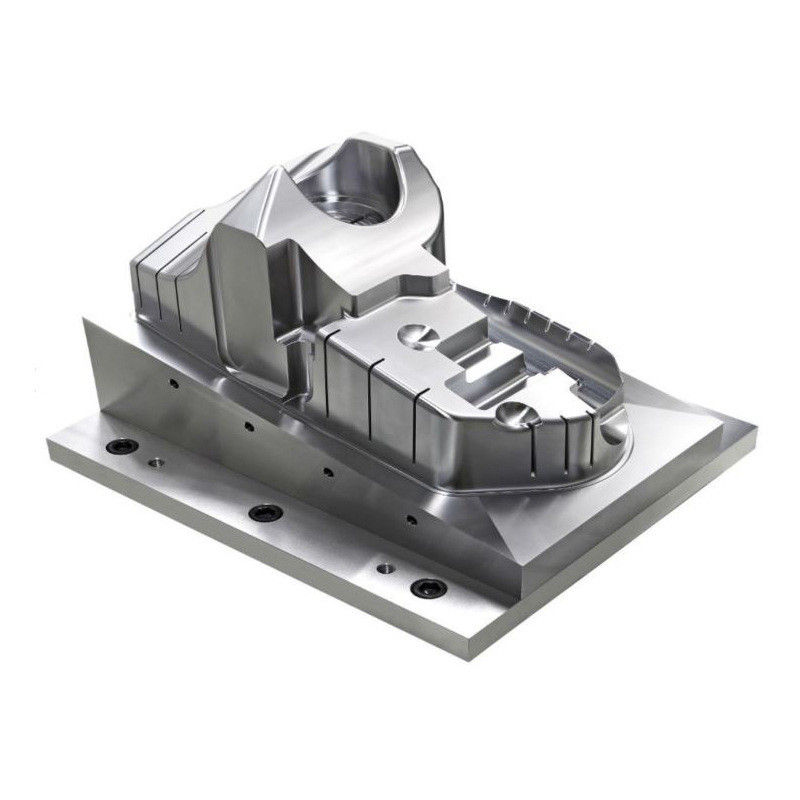

Because they guarantee that medical equipment and devices are made to the precise standards needed for use in surgical, diagnostic, and therapeutic applications, precision CNC components are essential to the medical business. The high-tech computer-controlled machining methods and tools used to create these components enable tight tolerances, accurate sizing, and superior finishes that satisfy the rigorous requirements of the medical sector.

The best materials, such as titanium, medical-grade stainless steel, and other exotic metals, are used to create our precision CNC components for the medical industry. These materials have been selected because of their remarkable strength, resilience to corrosion, biocompatibility, and capacity to survive the rigorous sterilizing procedures required in medical settings.

Our expertise lies in the creation, advancement, and manufacturing of precise CNC parts for an extensive array of medical uses, encompassing surgical tools, orthopaedic implants, dental apparatus, and equipment for diagnosis and treatment. Our group of very talented engineers and machinists possesses the knowledge and experience required to create complicated products with precise geometry and strict tolerances.

We make use of cutting-edge manufacturing tools and software at our facilities to guarantee that our precision CNC components not only satisfy but also surpass the strictest requirements of the medical sector. Every component we create is carefully inspected and tested before it is dispatched to our customers thanks to our quality control procedures.

In conclusion, the medical sector relies heavily on our precision CNC components, which enable sophisticated manufacturing processes for a variety of medical apparatus and equipment. Our dedication lies in collaborating with medical device producers and other relevant industry players to develop precise, dependable, and superior-quality components that cater to the specific requirements of the healthcare sector.

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Precision CNC Components for the Medical Industry.Sunbright look forward to cooperating with you.

2.Precision CNC Components for the Medical Industry Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

3.Precision CNC Components for the Medical Industry Feature And Application

Our precision CNC components for the medical industry are distinguished by their high-grade materials, which include titanium, medical-grade stainless steel, and other exotic metals. These materials have been selected because of their remarkable strength, resilience to corrosion, biocompatibility, and capacity to survive the rigorous sterilizing procedures required in medical settings. Our precision CNC components are made with cutting-edge computer-controlled machining tools and processes, enabling tight tolerances, accurate sizing, and superior finishes that satisfy the demanding specifications of the medical sector.

Numerous medical devices and applications make considerable use of our precision CNC components for the medical industry. These consist of:

Surgical instruments: Tools including forceps, scissors, clamps, and scalpels are made with our high-precision CNC components.

Orthopedic implants: We manufacture complex parts utilized in orthopedic procedures, such as implants for the knee, shoulder, and hip.

Dental devices: We produce the parts needed to create dental crowns, bridges, and implants.

Diagnostic and therapeutic equipment: Medical lasers, X-ray machines, and ultrasound machines, among others, depend heavily on our CNC components.

4.Precision CNC Components for the Medical Industry Details

High precision CNC machining is used in the production of precision CNC components for the medical industry.

Technical engineers and workshops adhere strictly to the certification standards of AS9100D and ISO9001 in their implementation and operations.

Before shipping, every part is thoroughly examined and subjected to zero tolerance quality control.