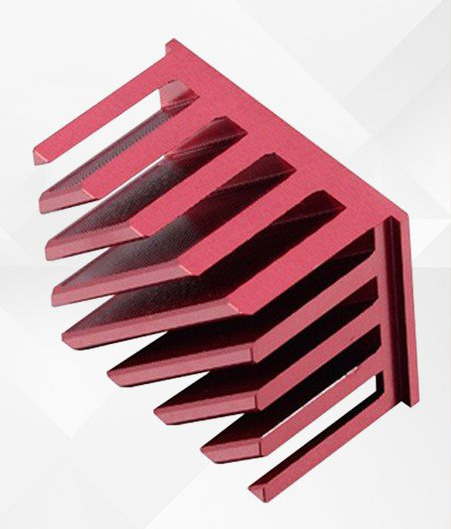

UAV Metal Parts

The UAV Metal Parts are still very important in the aviation industry. The necessary accessories for drones are these: propeller guards, spare propellers, GPS trackers, etc. are all necessary supplies for drones.

Product display

Product introduction

In practical application, the UAV Metal Parts must be more precise, and the more exquisite they are, the more they can reflect the processing level and quality. Compared with the advantages and characteristics, the product quality will generally be higher, so what are the characteristics of CNC machine tools for processing UAV metal parts?

1. First of all, CNC machine tools have higher productivity for processing UAV metal parts. CNC machine tool parts processing can produce and process several surface layers together. Compared with ordinary lathe production and processing, many process processes and time can be saved, and CNC machined parts can be processed. The quality of parts is also much smoother than that of ordinary lathes.

2. CNC machining of UAV metal parts has an irreplaceable effect at the level of new product research and development. Generally speaking, parts of different complexity can be processed according to programming, and the modification and refresh design plan only need to change the CNC The program flow of the lathe, which can greatly reduce the product development cycle time.

3. The degree of automation of CNC machine tools to process UAV metal parts is very sufficient, which greatly eases the labor efficiency of the staff. The workers do not have to operate the whole process like ordinary lathes in the production process. The purpose is to develop an observation on CNC lathes. inspection and regulation. However, the relative scientific and technological content of CNC machining is higher than that of ordinary lathes, so relative ordinary lathes require higher brains.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Shenzhen Sunbright Technology Co., Ltd. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.